Add 60 years to service-life of concrete in critical environments

Historically, the prime concern for concrete designers has been its resistance to mechanical stress, i.e. strength. In recent years, durability has emerged as equally important.

However, durability cannot be achieved with optimal W/C ratio, high compressive strength, more cement or air-incorporation alone.

To achieve concrete durability in critical environments, properties like low permeability, low shrinkage, self-healing and protection against chemical attack must be realized. Penetron Admix incorporates the technology that provides such properties and recent testing has shown it can add up to 60 years or more to a variety of concretes, including CEM II /B-P, CEM II / B–S and CEM III/A, in critical environments before the onset of corrosion.

These results are in line with ACI report 212.R3-10, which concludes that crystalline admixtures are the best PRAH (permeability reducing admixtures for Hydrostatic conditions) and increase durability of concrete.

Details of this durability testing are provided below.

Jozef Van Beeck

Director International Sales & Marketing

In order to establish the effect of Penetron Admix on the durability of concrete, a complete research project was executed at leading independent laboratories over a 2-year period. The testing included compressive strength, drying shrinkage, permeability, sulphate resistance, chloride diffusion resistance, freeze-thaw cycle resistance, self-healing ability, microscopic examination of crystalline formation and most importantly – a resulting service-life estimation of concrete treated with Penetron Admix.

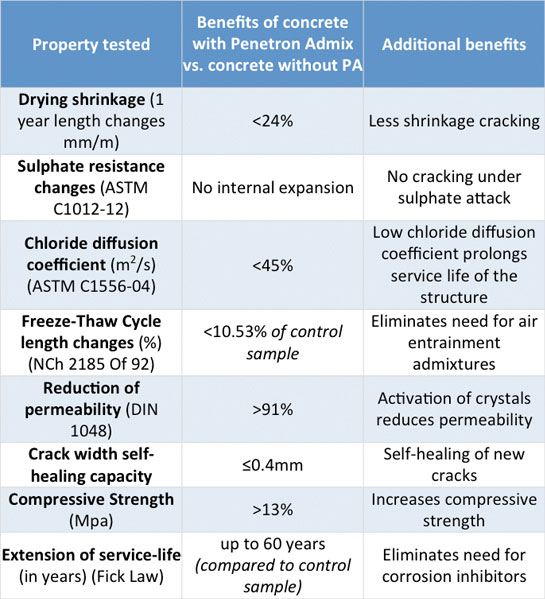

The results of this testing regime are summarized in the following table;

Moreover, it shows that Penetron Admix completely eliminates the need for silica fume, corrosion inhibitors and air-entrainment admixtures.

Each test result will be expanded upon in detail in these durability updates going forward – in this issue we will focus on the service-life estimation based on Chloride diffusion only;

Pernambuco Stadium.

Chloride migration testing performed according to ASTM C1556 yielded the following results, with and without Penetron Admix;

Table 2. Apparent chloride diffusion coefficient

| CONCRETE | Time (Days) | Initial Content Cl Ci (%) | Superficial Content Cl Cs(%) | Apparent Diffusion Coefficient Cl(m2/s) |

| C WITHOUT PA | 35 | 0,023 | 1,084 | 7,20E-12 |

| C1 WITH PA | 35 | 0,022 | 1,304 | 4,90E-12 |

| C2 WITH PA | 35 | 0,008 | 1,481 | 4,66E-12 |

C and C1: CEM II/B-P

C 2: CEM II / B-S

PA : Penetron Amdix

Using the 2nd Fick law of diffusion, we can then estimate the lifespan of concrete based on the chloride migration coefficient and the cover of steel, obtaining the following results;

(where

C(x,t) = Chloride ion concentration at a distance x from the surface of the concrete by an exposure period t (material mass %).

Cs = Chloride ion concentration on the surface of the concrete (material mass %)

x = Coating thickness (m)

t = Exposure time to chloride ion (years)

Dc = Chloride diffusion coefficient (m2 / s)

erf = Error function.

Dc(t) = Chloride diffusion coefficient at time t (m2 / s)

D0 = Chloride diffusion coefficient at time t0 (m2 / s)

t0 = Initial chloride diffusion time (years)

t = Time chloride diffusion control (years)

m = used 0.5 )

Therefore, in an environment with chloride concentrations 4.7 times higher than true marine environments, Penetron Admix treated concrete can add up to 60 years and more to the service life of a conventional concrete, before the onset of corrosion.

A second chloride migration test in accordance with Nordtest, done on extremely durable concrete mix design CEM III/A, still yielded another 40 years of service life extension with Penetron Admix.